Planar Elbow Manipulator — Design & Control

A 2-DoF planar elbow manipulator that uniquely met every mechanical requirement in ME408, integrating robust CAD, power electronics, and dual-loop control for precise trajectory tracking.

1 · Overview & Motivation

This solo ME408 project (Sabancı University) produced the only design in a class of 20+ that satisfied all structural, weight, and accuracy specs.

The goals were:

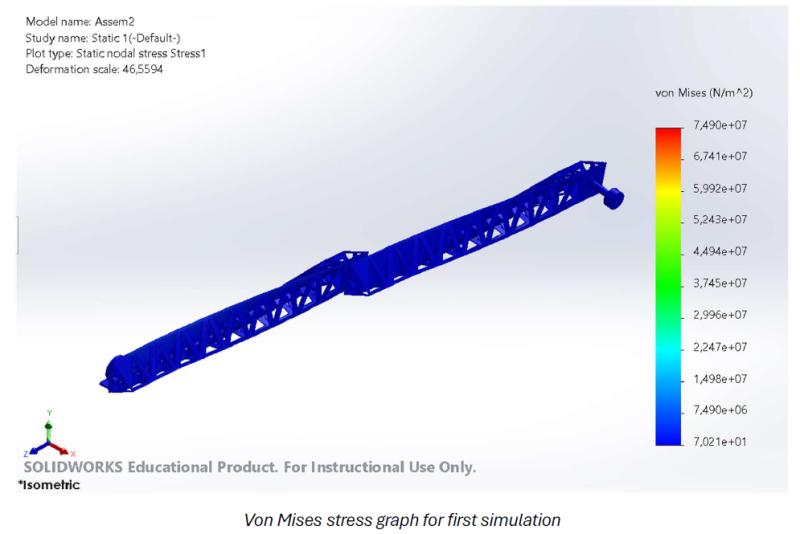

- Light-yet-strong mechanics — optimized with FEA

- Clean power delivery — custom buck-boost converter

- High-precision motion — gravity-compensated PI/PID dual-loop control

| Metric | Target / Result |

|---|---|

| Safety factor | > 2 (FEA) |

| Mass reduction | 18 % vs initial |

| Tracking error | ≤ 0.35 ° RMS @ 60 °/s |

| Loop latency | 2.4 ms @ 1 kHz |

2 · Mechanical Design

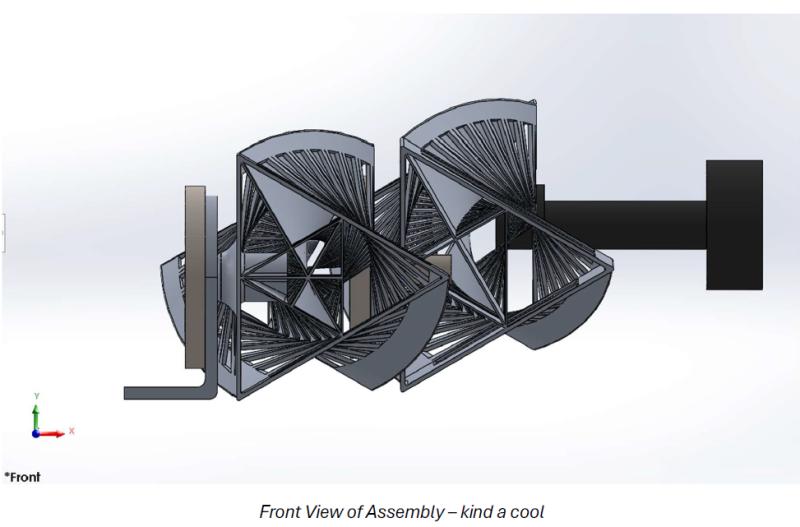

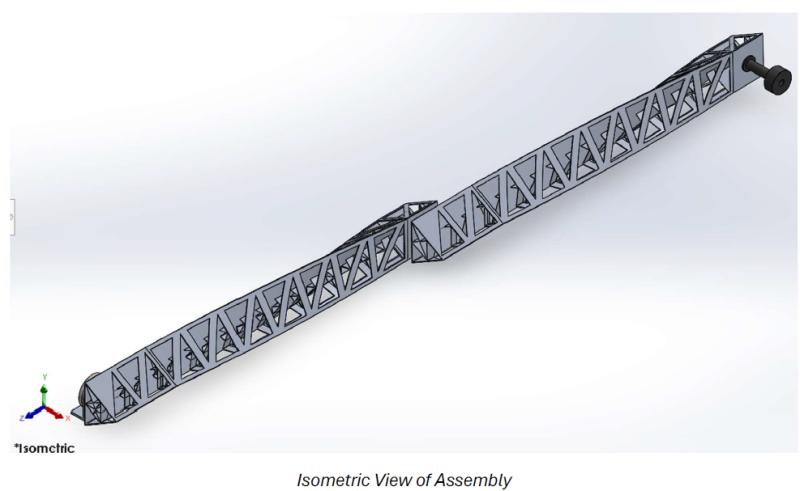

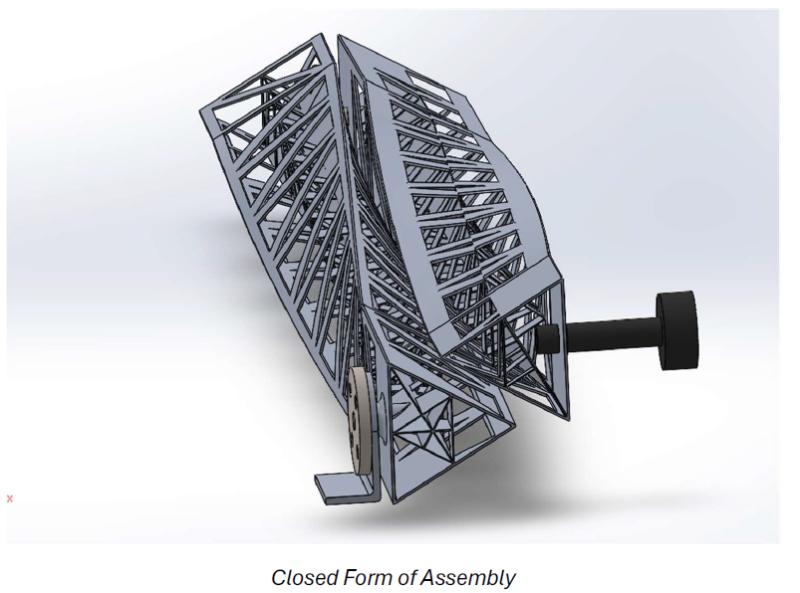

- CAD in SOLIDWORKS with topology-inspired link geometry

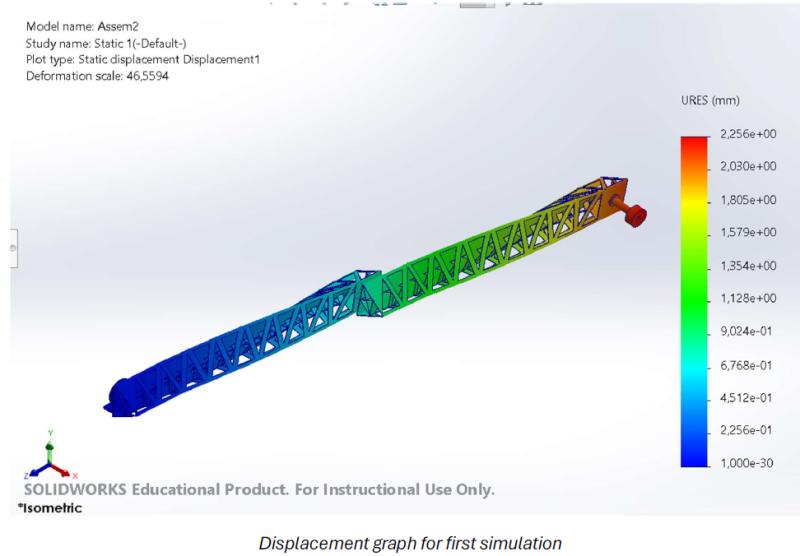

- Static & dynamic FEA → safety factor > 2 while trimming 18 % mass

- Modular joints for quick bearing replacement and encoder mounting

3 · Power Electronics

- Buck-boost converter designed in LTspice

- 7 % voltage ripple, < 5 % inductor current ripple at 1 A load

- Integrated Hall shunt for inner-loop current sensing

4 · Control Architecture

| Loop | Controller | Inputs | Outputs |

|---|---|---|---|

| Inner | PI | Motor current, Vin | PWM duty cycle |

| Outer | PID + g-comp | Joint angles, desired θ | Motor current set |

- Trajectories generated from inverse kinematics; simulated in MATLAB/Simulink

- Achieved ≤ 0.35 ° RMS tracking error on a 60 °/s sinusoid

5 · System Integration & Validation

All subsystems were co-simulated:

- Mechanics → SOLIDWORKS Motion

- Electronics → LTspice transient + Bode analyses

- Control → Simulink real-time plant-in-the-loop

CAD renders and closed-form workspace analysis.

Key FEA results confirming deformation < 0.12 mm and stress well below yield.

Completed for ME408 — Mechatronic System Design (Fall 2024).