2-DOF Manipulator — Model-Based Real-Time Control

MATLAB/Simulink and TI C2000 control stack: computed-torque, PD with gravity compensation, and joint/task-space transforms for millimetre-level trajectory tracking on a 5-link planar robot in real time.

1 · Overview & Motivation

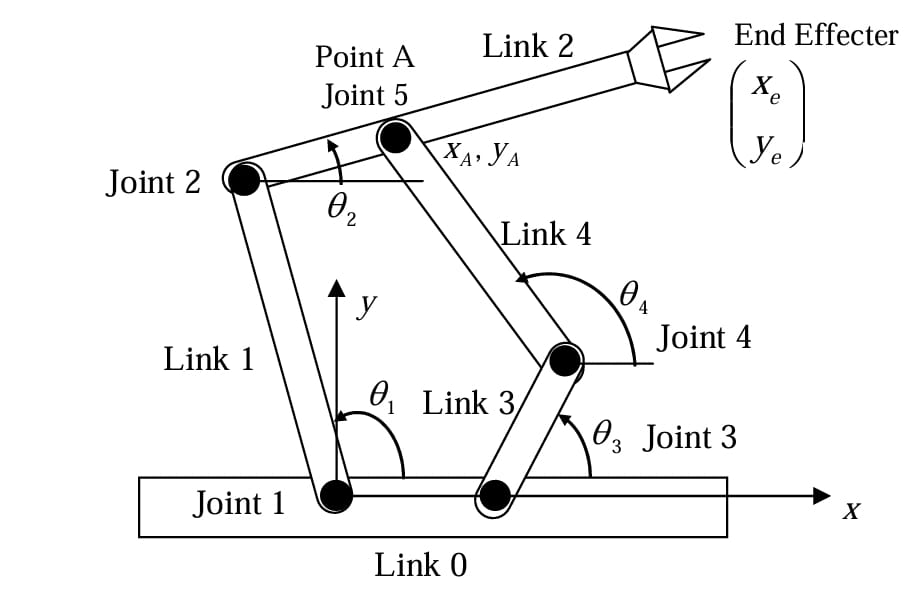

This project—completed for ME403 — Introduction to Robotics (Spring 2024, Sabancı University)—developed a model-based real-time controller for a planar 2-DOF, 5-link manipulator.

Key goals:

- Achieve sub-millimetre end-effector accuracy on dynamic paths

- Bridge simulation (SIL) and embedded deployment (HIL) seamlessly

- Provide a re-usable MATLAB/Simulink template for undergraduate robotics labs

2 · Control Architecture

The stack follows a computed-torque framework augmented with a PD + gravity compensator.

Software is split into three Simulink model hierarchies that map 1-to-1 onto TI C2000 peripherals.

| Layer | Role | Runs On |

|---|---|---|

| Task-Space Planner | Generates x-y trajectories | Host PC (SIL/HIL) |

| Controller Core | Inverse kinematics + computed-torque PD | TI C2000 (HIL) |

| Motor Interface | PWM output + encoder decoding | TI C2000 (HIL) |

Control Loop (1 kHz)

- Trajectory Sample – desired end-effector pose

- Inverse Kinematics – joint targets (θdes, ẋdes)

- Computed-Torque Law – τ = M(q)[*]α + V + G

- PD + G Compensation – fine-tunes stiffness & damping

- PWM Generation – duty cycles to H-bridges

- Encoder Feedback – closes joint-space loop

% Simulink MATLAB Function: Computed-Torque PD

tau = M(q)*(qdd_des + Kd*(qd_des - qd) + Kp*(q_des - q)) ...

+ V(q, qd) + G(q);

3 · Simulation & Real-Time Testing

| Stage | Environment | Purpose |

|---|---|---|

| SIL | Simscape Multibody + MATLAB ODE45 | Verify kinematics, dynamics, and controller logic without I/O latency |

| Processor-in-the-Loop | TI C2000 F28379D + external mode | Measure computation time (< 180 µs / step) |

| HIL | Full manipulator with DC motors & optical encoders | Validate closed-loop tracking and load tolerance |

Total transition time from SIL to validated HIL: < 3 hours thanks to code-gen-friendly model structure.

Completed for ME403 — Introduction to Robotics (Spring 2024, Sabancı University).